Watch How Apple 3D Prints Watches by Blasting Powdered Titanium with Lasers

In an era where innovation defines the path of technology, Apple consistently stands out as a pioneer of cutting-edge methodologies. One of their latest advancements involves an intriguing process: 3D printing titanium watches using laser technology. This article delves into the fascinating world of additive manufacturing and how Apple is redefining watchmaking with this revolutionary technique.

The Evolution of Watchmaking

Traditionally, watchmaking is an art that combines meticulous craftsmanship with mechanical precision. However, as technology progresses, the industry is seeing a shift toward modern manufacturing processes. 3D printing has emerged as a game-changer, allowing for unprecedented design flexibility and precision.

With the introduction of additive manufacturing, brands are not only able to reduce waste and minimize production times but also push the boundaries of design. Apple’s mastery of 3D printing technology takes this to a whole new level.

The Magic of 3D Printing

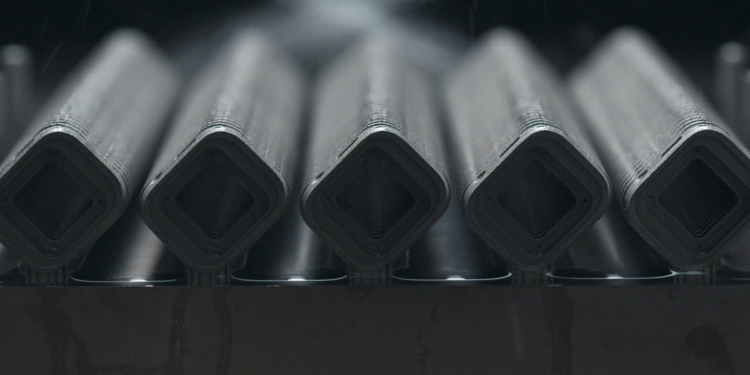

At its core, 3D printing—also known as additive manufacturing—allows for the creation of three-dimensional objects from a digital file. In the case of Apple’s watches, the company employs a sophisticated process that involves blasting powdered titanium with lasers.

-

Powdered Titanium as a Building Block:

Titanium is a remarkable material in the world of watchmaking. Known for its lightweight yet durable properties, it’s resistant to corrosion and provides an elegant finish. Apple utilizes fine titanium powder as the primary building material, which offers the ideal combination of strength and aesthetic appeal. -

Laser Sintering Process:

The heart of the manufacturing process lies in laser sintering. A laser beam is used to selectively fuse the powdered titanium particles together layer by layer. This process occurs within a controlled environment, ensuring that each iteration of the watch component is perfect before moving onto the next layer. The precision of the laser allows for intricate designs that would be impossible with traditional manufacturing methods. -

Post-Processing:

Once the printing process is complete, the newly-formed watch components undergo post-processing. This includes removing any excess powder, refining the surface finish, and conducting quality assurance checks. Each piece is meticulously inspected to meet Apple’s high standards, ensuring that the final product is not only beautiful but functional as well.

Advantages of Laser-Printed Watches

The use of 3D printing in watch manufacturing offers several advantages:

-

Customization: Every consumer has unique preferences. Through 3D printing, Apple can easily customize watch designs to cater to individual tastes. This flexibility opens new avenues for personalization in luxury goods.

-

Sustainability: Traditional watchmaking often produces significant waste materials, but additive manufacturing minimizes excess. By using only the necessary amount of titanium powder, Apple demonstrates a commitment to sustainability and efficient resource usage.

-

Innovation in Design: With the ability to produce complex geometries without the constraints of conventional manufacturing techniques, designers can experiment with new forms and structures. This leads to more innovative and aesthetically pleasing designs.

Conclusion

Apple’s foray into 3D printing through the use of laser technology to create titanium watches represents not just a leap in manufacturing, but a statement of the future of horology. As they continue to refine this process, we can expect to see even more groundbreaking designs and capabilities.

In a world where technology meets artistry, Apple is shaping the future of watchmaking, ensuring that their products remain not only functional but also masterpieces of modern engineering. With each tick of the clock, they remind us that the intersection of tradition and innovation can yield truly extraordinary outcomes. As consumers, we eagerly anticipate what’s next from this ever-evolving brand.